À propos de LIL

Crushing and Screening Handbook - AusIMM

2021.6.24 all high-capacity primary hard rock crushing applications. Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their

Voir plus

Primary Crusher vs. Secondary Crusher:

2023.2.28 Both primary and secondary crushers are used in a variety of real-world applications. In mining, primary crushers are used to break down large rocks and stones into smaller particles for further processing. Secondary

Voir plus

What Is Primary, Secondary, and Tertiary

2021.12.13 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of

Voir plus

What Is Primary, Secondary, and Tertiary Crushing?

2024.9.6 Secondary crushing (or intermediate crushing) accepts the material from the primary crushing stage and reduces it even further, whether for final product sizing or in

Voir plus

Primary Crushing - SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry” crushing

Voir plus

Downstream Crushing Options for Secondary,

2021.4.12 Jaws and gyratories will most often be found in the primary crushing stage, while cones, impactors and roll crushers are most often used in the secondary, tertiary and quaternary crushing stages. Knowing which

Voir plus

Wills' Mineral Processing Technology, 8th Edition

Crushing is the first mechanical stage in the process of comminution in which a principal objective is the liberation of the valuable minerals from the gangue. Crushing is typically a dry operation

Voir plus

Types of Crushers: Choosing the Right One for

2024.7.17 Crushing is a multi-stage process that includes primary crushing, secondary crushing, and tertiary crushing. Different types of crushing equipment are used at each stage to meet various crushing requirements.

Voir plus

Stone Crushers: A Technical Review on

2022.5.14 A single type of crusher is not sufficient enough to convert the large size rock into required size stone. So, the crushing process involves primary, secondary and tertiary crushers during the whole crushing cycle to

Voir plus

AMIT 135: Lesson 5 Crushing – Mining Mill

Explain the stages involved in crushing operation (Primary, Secondary and Tertiary) ... Secondary crusher: 6:1 to 8:1; Tertiary crusher: 10:1 Therefore, if a 3 mm crusher product is required, maximum feed size to the secondary crusher

Voir plus

Types of Crushers: What You Need to Know

The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits. Primary crushing involves using a large object as the initial force to break down very large and hard rocks and

Voir plus

Primary Crushing: A Comprehensive Guide - JXSC

2024.2.23 Although cone crushers are traditionally utilized in secondary and tertiary roles, they can adapt to primary crushing for medium-hard to hard materials. They are capable of handling input sizes up to 600mm and can produce output sizes ranging from 20mm to 200mm.

Voir plus

Primary and Secondary Crushing: Understanding the Basics

2023.2.28 Secondary Crushing. Secondary crushing is the second stage of crushing that takes place after the primary crushing. The secondary crusher is the equipment that reduces the size of the materials further, after they have been reduced by the primary crusher. The secondary crusher has a size reduction ratio ranging from 3:1 to 5:1.

Voir plus

Crushers: 5 types and their main failures - Dynamox

2024.4.19 The crushing process is divided into three main stages: primary, secondary, and tertiary. In the primary stage, heavy machinery is used to reduce the size of the material coming from the mines (blocks from 1000 to 500 mm to 300-100 mm). ... The gyratory crusher can be used in both primary and secondary crushing. Its main advantage lies in its ...

Voir plus

Primary Crushing - SpringerLink

Primary crushing brings run-of-mine ore down to a maximum size of the order 4″ to 6″ in average diameter; secondary crushing receives feed at −6″ and reduces it to below “Dry” crushing includes work on ore as mined, which may be somewhat moist when delivered. It is succeeded by comminution in water, arbitrarily called “grinding”.

Voir plus

Crushing in Mineral Processing - Eastman Rock Crusher

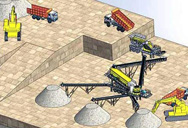

2020.4.20 The picture above shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen into a 0-20 mm fraction and typically a 20-150 mm fraction. The 0-20 mm fraction contains soil etc. and is generally considered to be of poor quality.

Voir plus

Crushing and Screening Handbook - AusIMM

2021.6.24 secondary, tertiary or quarternary crushing ap-plications. High performance technology. Impact crushers – primary and secondary machines for soft and medium-hard materials. High reduction ratios. Can eliminate need for a tertiary crushing stage. Spare and wear parts – genuine parts always close to you, no matter where you are located worldwide.

Voir plus

What Crusher Should You Choose for Primary Crushing?

2024.6.28 Wide application: Suitable for both dry and wet crushing, for materials with up to 15% moisture. One-time forming: Eliminates the need for primary and secondary crushing, reducing costs by approximately 40%. Large feed opening: Handles feed sizes up to 1000 mm, making it ideal for coarse crushing. Non-clogging: Designed to ensure smooth flow of high

Voir plus

What Are the Differences Between The 7 Types

2024.7.15 Although their common and basic function is reducing large size of rock into small size, they are applied to different crushing stages like primary, secondary, tertiary, quaternary stages. It is necessary to clarify what are the

Voir plus

Wills' Mineral Processing Technology, 8th Edition

Crushing is the first mechanical stage in the process of comminution in which a principal objective is the liberation of the valuable minerals from the gangue. Crushing is typically a dry operation which is performed in two- or three-stages (i.e., primary, secondary, and tertiary crushing).

Voir plus

Primary, Secondary Tertiary Sources - Grad

1 天前 As with primary sources, secondary sources have their own set of pros and cons. Some of the main advantages include: Convenience: secondary sources are often easier to access and use than primary sources, as they are

Voir plus

Plant flowsheet: Primary crushing, secondary and tertiary crushing ...

Download scientific diagram Plant flowsheet: Primary crushing, secondary and tertiary crushing, agglomeration, and heap leaching. from publication: Model based decision support system for the ...

Voir plus

Primary vs. Secondary Crushers: Understanding the

2023.2.28 Comparison between Primary and Secondary Crushers. Primary and secondary crushers serve different functions in the crushing process, and understanding the differences between them can help determine which type of crusher is best suited for a given application. Differences in Function, Design, and Operation

Voir plus

Schematic description of the crushing plant, (1) primary

Download scientific diagram Schematic description of the crushing plant, (1) primary crusher, (2) secondary crusher, (3) tertiary crushers, (4) final screens and (5) a switch for changing the ...

Voir plus

Crushing 101 – Different types of crushers for distinctive needs

2020.12.17 Horizontal shaft impact crushers are used in primary, secondary or tertiary crushing stage. They reduce the feed material by highly intensive impacts originating in the quick rotational movement of hammers or bars fixed to the rotor. The particles produced are then further fragmentated inside the crusher as they collide against crusher chamber ...

Voir plus

What is Primary, Secondary and Tertiary Crushing? - LinkedIn

2022.6.27 Secondary crushing is the second stage of material processing after the first crushing. After that, the product to be crushed will pass through a second crusher or a cone crusher, which is ...

Voir plus

Secondary Tertiary Crushing Circuits - 911Metallurgist

2015.7.25 Open Circuit Crushing. In this sector on Secondary and Tertiary crushing, we will continue the practice of talking about different equipment, the work it does, and the effects of what I call operating variables. These variables are anything that affect the performance of the equipment. Lets begin with an over view of these two crushing stages.

Voir plus

(PDF) COMPARISON OF SECONDARY CRUSHING

2020.9.20 Likewise, 4S crushing had primary, secondary, tertiary and quaternary crushers as Jaw, Jaw, HSI and VSI (vertical shaft impactor), respectively. The 4S had an additional VSI crusher to 3S crushing.

Voir plus

Consulter en ligne

- concasseurs de béton de vacances floride

- machines pour l'extraction du minerai de fer

- Calcaire Concasseur Portable A Vendre En Malaisie

- concasseur de pierres machine à Italie

- suède aperçu de l'équipement minier

- concasseur de pierre a Goa

- escoria triturador de multa por venda

- machines de meulage de métal fixation

- equipement de raffinage de cuivre

- SBM chine concasseur à percussion

- l'étape de broyage primaire

- baryte séparation par gravité

- le minerai de fer avec le fournisseur de plante de la concentration

- concasseurs à mâchoires ingénieurs concasseur à mâchoires

- Cone Mobiles Prix De Concasseurs