À propos de LIL

Comparing Mineral Processing Equipment for

4 天之前 It may be noted that gold ores are of different types depending on whether they are Free-milling or refractory. Ore which can be processed using crushing and gravity concentration methods are ...

Voir plus

Complete process and equipment solutions for

2021.9.17 Metso Outotec can deliver the three main oxidative processes for the treatment of refractory gold concentrates – BIOX, pressure oxidation, and roasting – and also supply equipment for ultra-fine grinding as a fourth, non

Voir plus

Recovery Refractory Resources - SGS

2022.7.6 refractory gold ore is gold-containing ore that is resistant to recovery by direct cyanidation and carbon adsorption processes. More specifically, it is an ore that has a gold

Voir plus

Zhengzhou Rockstone Industrial Technology Co,. Ltd

Rockstone is committed to providing stone crushing equipment, powder grinding mills, ore dressing equipment, building materials equipment and environment protection equipment for you.

Voir plus

Integrated Technology for Processing Gold-Bearing Ore

2021.9.24 The scientific novelty of the work lies in the extraction of gold from refractory ore with sorption activity using sequential processes of gravity separation and flotation of gold

Voir plus

Flowsheet Development of A Refractory Gold Ore To

2024.5.14 have achieved positives outcomes for what is a complex refractory gold ore. The RGO flowsheet consists of primary single toggle jaw crushing of the ore followed by secondary

Voir plus

Pretreatment of refractory gold ore by curing with

2024.2.19 Different from traditional high-temperature roasting, concentrated sulfuric acid was used as both an oxidant and leaching agent in a sulfide-encapsulated refractory gold ore

Voir plus

Gold and Silver Extraction - SpringerLink

2019.12.15 Before cyanidation and flotation processes were introduced, gold recovery and extraction included combinations of crushing and grinding of the ore, followed by roasting, fine

Voir plus

FLOWSHEET DEVELOPMENT FOR GOLD OREBODIES - SGS

refractory ores. The mining industry uses a “rule of thumb” of 80% gold recovery to define the transition from a refractory to a non-refractory gold ore. Ones under 80% are considered

Voir plus

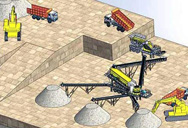

Application of ore crushing equipment in refractories_Henan

2024.1.17 Application of ore crushing equipment in refractories Ore crusher is a kind of mechanical equipment dedicated to the crushing processing of ore and other materials.

Voir plus

Copper Ore Processing Plants, Flow And

2024.11.11 A single sulfide ore is usually treated by flotation process, using crushing-grinding-classification-flotation-concentration process to select a single copper sulfide ore as copper concentrate. Copper ore beneficiation

Voir plus

Refractory Ore Crushing Equipment

However, large gold concentrators usually adopt three stage one closed circuit ore crushing process. Jaw crusher is used for coarse crushing, cone crusher for medium crushing or fine crushing, ball mill equipment is used in grinding stage, grid type ball mill is used for primary grinding, overflow type ball mill is used for secondary grinding.

Voir plus

China Fine Screening Equipment, Stone Crushing

Henan Yuanren Mining Equipment Co.,Ltd: Fine Sieving Equipment manufacturer, fracking sand screen, large capacity, 20-40-80-120 mesh separator, quarry crushing plant factory, crushing and screening equipment

Voir plus

How to Process Copper Ore: Beneficiation Methods and Equipment

2023.3.13 Then the crushed materials are sent to the grinding equipment, and the final particle size of the copper ore is reduced to 0.15-0.2mm. Copper ore crushing process 1. Beneficiation methods of copper sulfide ore Copper sulfide can be divided into single copper ore, copper sulfur ore, copper-molybdenum deposit, copper nickel, carrollite and so on.

Voir plus

Comparing Mineral Processing Equipment for Different Ore

4 天之前 It may be noted that gold ores are of different types depending on whether they are Free-milling or refractory. Ore which can be processed using crushing and gravity concentration methods are ...

Voir plus

Magnesite Grinding Equipment Production Line - sbmmill

2021.10.29 Jaw crushers are widely used as crushing equipment in the magnesite grinding production line. It is mainly used for the primary crushing operation of the raw material magnesite so that the crushed magnesite meets the particle size requirements required by the next construction. ... SBM provides non-metallic ore grinding/crushing and screening ...

Voir plus

Refractory raw materials processing procedures and broken crushing

2018.1.17 Although there is no above closed-flow shortcomings, but the process is complex, requiring more ancillary equipment. The advantage is higher crushing efficiency, easy to reach the degree of particle material requirements. Usually refractory raw materials broken open-flow, and crushed by closed-flow circulating crushing.

Voir plus

Engineering Ceramics in Mining Mineral Processing

2024.1.4 At Saint-Gobain Performance Ceramics Refractories, we provide precision-made engineered ceramics for numerous touchpoints in the mineral processing chain, from ore extraction, crushing, grinding, separation, washing, processing and transporting. Here we will highlight a few of our proprietary engineered ceramic products for key application ...

Voir plus

Henan Mining Machinery and Equipment Manufacturer - Stone crushing ...

2019.9.2 Caesar Heavy Machinery is a famous mining crushing equipment and mineral processing equipment manufacturer in China for many years, and it can provide customers grinding equipment and other products with high quality. ... Ore beneficiation equipment, sand making equipment, crushing equipment and powder grinding equipment, which are widely

Voir plus

5 Steps to Process Andalusite–An Excellent

2024.5.30 This process is designed with 5 steps. Crushing and grinding refine the raw ore, magnetic separation removes magnetic minerals, gravity separation further removes impurities, and foam flotation increases the

Voir plus

ASTM C133 Crush Modulus Rupture Refractories

1 天前 ASTM C133 determines the cold crushing strength and the modulus of rupture (MOR) of dried or fired refractory shapes of all types. This test method determines room temperature flexural strength in 3-point bending for cold

Voir plus

Steps Involved in the Production of Refractories

2023.11.6 These kinds of refractories are produced using operations that release chromium compounds, including ore crushing, grinding, material drying and storing, and brick burning and finishing. The drying, calcining, and fire

Voir plus

Gold Ore Roasting Plant - 911Metallurgist

2016.6.1 The ore is blended prior to being fed into the crushing circuit. The ore passes through crushing and grinding circuits to the Roaster circuit then to the Carbon and Leach circuit at a designed rate of 12,000 tpd. ... REFRACTORY ORE FUEL VALUE (FV) CALCULATION MATRIX ... An emergency water tank provides gas cooling to protect process equipment ...

Voir plus

Zhengzhou Rockstone Industrial Technology Co,. Ltd

Zhengzhou Rockstone Industrial Technology Co., Ltd is a large mining machinery manufacturer and exporter, located in Zhengzhou, Henan, China. Our main product categories include stone crushing machine, powder grinding machine, mineral processing equipment, building materials equipment, wood processing equipment, environment protection equipment, etc.

Voir plus

Crushing and Grinding Wet Sticky Ore - 911Metallurgist

2016.5.10 Unless this is done, crushing becomes a constant source of trouble resulting in lost production and high milling cost. In some areas rainfall is high for prolonged periods. This seriously affects ore handling and continuity of operations not only in open pit but also underground mining. Solution to the Wet Ore Processing Problem

Voir plus

A systematic review of sustainable gold extraction from raw

2022.3.1 It takes place after primary crushing, when the raw ore exhibits a size-related grade differentiation between lump fragments of the host rock and finer particles belonging the mineralised body. ... Each refractory gold ore has distinctive mineralogical characteristics, which presents unique challenges during metallurgical processing ...

Voir plus

Direct Cupric Chloride Leaching of Gold from Refractory Sulfide Ore ...

2021.4.13 The selected refractory ore minerology for the simulation is presented in Table 1. The gold and silver content in the concentrate was 38.7 and 33.0 ppm, respectively. ... In addition, electrical power consumption was calculated for all the key equipment (for different scenarios and cases) in the process based on the mass balance. ...

Voir plus

Ore Processing Equipment - Hongxing Mining Machinery

2024.8.6 Product information. Ball mill is the key equipment for re-crushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals, and glass ceramic industry.

Voir plus

>> Next:Avantages Et Les Inconvenients De Broyeur A Boulets

Consulter en ligne

- Le broyeur à boulets alubit 7 8 en

- cône hydraulique concasseur à concasseur india du nigeria commencer

- de 1000 watts axe vertical eolienne

- electrik machine chimique de meulage

- concasseur occasion à vendre en EAU

- suivre machine de concassage monte a vendre inde

- exploitation de la mine de charbon conjunto

- concasseur mobile typique

- utilisé 1500 moulin de kw à vendre sel

- écran de gypse et dessins de plantes concasseur

- de concassage de pierre entreprises en Nouvelle Caldonia

- Broyeur à béton aux EtatsUnis à vendre

- convoyeur bande occasion

- grilles de criblage pour carrires

- Indonésie vendre et louer Indonésie béton mobile