À propos de LIL

Belt Conveyors for Bulk Materials - Fifth Edition - Chapter 6

2018.11.14 The belt conveyor engineering analysis, infor- mation, and formulas presented in this manual represent recent improvements in the concepts and data which have been

Voir plus

SUBSTANTIATION OF PARAMETERS AND EFFICIENCY OF

2022.7.29 A sandwich belt high angle conveyor (hereinafter, HAC) com-posed of conventional time-tested assemblies, including traction members with smooth surfaces, which

Voir plus

Conveying and Storing in the Mining Minerals

2020.11.10 These belt bucket elevators are suitable for the lifting of fine materials to extreme hights and for a large capacity range. AUMUND steel cable belts with additional cross

Voir plus

Control and drive systems for mine conveying - ABB

2024.3.18 Gearless conveyor drives from ABB are used to operate the world’s most powerful belt conveyor system, with a design capacity of 11,000 tonnes per hour, at the

Voir plus

7 Belt conveyors - Springer

2017.8.25 The greatest use of belt conveyors at present is in the mining and quarrying industry. However, there is now effectively no restriction on the type of bulk materials that can

Voir plus

ANALYSIS OF CONVEYOR DRIVE POWER

2021.3.31 Abstract: This article presents the analysis of conveyor drive power requirements for three typical mining conveyors. One of the conveyors was found not to be

Voir plus

Dedicated to improving bulk material handling

2020.6.26 The belt conveyor, stacking and bucket-wheel reclaiming system enables high capacities of copper ore to be leached and the “spent ore” to be discharged, occupying a

Voir plus

Mining Equipment and Conveyor Belts - RWE

2023.5.19 Mining Equipment and Conveyor Belts. Our mining experts can develop equipment specifications that match the demands of each mining project, assist in design

Voir plus

(PDF) Analysis of Conveyor Drive Power Requirements in the Mining

2020.12.9 The paper compares various metrics of conveyor belt condition, including those based on age (calendar working time and service life as a percentage of expected operating

Voir plus

Mining guide: Conveyor belt monitoring and control in mines

2018.12.19 Belt malfunction also poses a significant safety threat, with the Mine Safety and Health Administration (MSHA) reporting that three of the 25 fatalities recorded at US mines in 2018 involved conveyor belts; two accidents involved a worker being crushed between a conveyor belt and another piece of machinery as they were moved, and the third ...

Voir plus

Numerical Study on the Fracturing Mechanism of the Belt Conveyor ...

2022.8.8 Dagushan Iron Mine is a large-scale open-pit mine. In this mine, the belt conveyors residing in the rock slope are employed for ore haulage. However, after the − 210 m bench was excavated, many ...

Voir plus

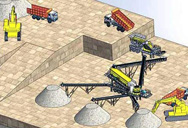

Minerals Mining Industry: Bulk Handling and Conveyor

Transportation in mines. The excavation of ores, coal, and minerals leads to ever-increasing distances between the excavation site, the shaft haulage, and the belt conveyor.These fluctuating distances are a big challenge for the mining industry, requiring flexible transport systems to move the bulk material from the excavation site to the overland conveyor.

Voir plus

Dedicated to improving bulk material handling

2020.6.26 downhill regenerative belt conveyor and first high capacity leach pad bucketwheel reclaimer. High in the Atacama Desert of Chile is the El Abra mine. In 1996, TAKRAF designed and built the largest capacity downhill regenerative belt conveyor system. The 8,600 t/h, 9.5 km long overland conveyor descends over 500 m in

Voir plus

Conveying and Storing in the Mining Minerals

2020.11.10 application determine the conveyor. Accurate planning is a most important issue here, because it is basic for the plant‘s profitability. This philosophy made AUMUND Foerdertechnik a leading company in bulk materials handling in the mining and minerals, cement, steel, and power industry. Hence AUMUND consequently offers a broad range of

Voir plus

Sempertrans-Australia Conveyor Belts Semperit

Explore Sempertrans Australia's high-quality conveyor belts designed for the demanding conditions of the mining industry. Certified fire resistance, enhanced durability, and compliance with Australian standards. Elevate your mining operations with

Voir plus

Conveyor Belt Solutions for every mining task

2020.4.14 Flowchart of mining and manufacturing 4 of iron concentrate Flowchart of mining, processing, combustion 6 ... Conveyor belts for every mining application ContiTech is a multinational corporation with operations in almost all countries around the world. We provide a wide range of conveyor belts and related products, longtime

Voir plus

[PDF] Testing belt conveyor resistance to motion in underground mine ...

2017.1.2 Abstract This paper presents a method of measuring the resistances to motion of a single three-roller idler set with the use of a specially designed measuring stand. The design and calibration of the stand are described. The stand allows to conduct measurements in real operating conditions and with variable stream of bulk material. The frame with the data

Voir plus

A Faster and Lighter Detection Method for Foreign Objects in Coal Mine ...

2023.7.10 A Faster and Lighter Detection Method for Foreign Objects in Coal Mine Belt Conveyors. July 2023; Sensors 23(14):6276; DOI:10.3390 ... Download full-text PDF Read full-text. Download full-text PDF ...

Voir plus

Study and Design of Belt Conveyor System in Coal Mines

Request PDF On Jan 24, 2016, Mainak Mukherjee published Study and Design of Belt Conveyor System in Coal Mines Find, read and cite all the research you need on ResearchGate

Voir plus

(PDF) An Effective Belt Conveyor for Underground Ore

The applied solution is described below. 2. Solutions for underground belt conveyors for transporting ore Theoretical and experimental (performed in the laboratory premises and in-situ) investigations in the field of heavy duty mining belt conveyors main resistances to motion have been carried out for many years [6,7,8].

Voir plus

SUBSTANTIATION OF PARAMETERS AND EFFICIENCY OF

2022.7.29 Heavy-duty high angle belt conveyors in operation in open pit mines in the world Open pit mine, company, conveyor installation year Cargo Bulk density, t/m3 Capacity, t/h Elevation angle, deg ... Iron ore 1.9–2.2 1200 36 124.0 315.0 1600 2.90 110 710 Mikhailovsky GOK, Russia, 2020

Voir plus

(PDF) Maintenance Management of Mining Belt Conveyor

2017.9.6 Belt conveyor network is an important transportation form used in underground copper ore mines. Effective maintenance of this infrastructure is critical-serious failure of single conveyor might ...

Voir plus

(PDF) Intelligent Detection of Foreign Matter in Coal Mine ...

2022.7.5 This paper applies the CenterNet target detection algorithm to the foreign object detection of coal conveying belts in coal mines. Given the fast running speed of coal conveying belts and the ...

Voir plus

(PDF) Conveyor belt technique design and calculation

2023.11.3 Download full-text PDF Read full-text. Download full-text PDF. Read full-text. Download citation. Copy link Link copied. ... The conveyor belt plays the major part in the whole system and has to over-

Voir plus

(PDF) An Effective Belt Conveyor for Underground Ore

2017.12.1 A base (reference) belt conveyor representative for the group of belt conveyors used in copper ore mines was selected for the tests. The results of research into the resistance to motion of a ...

Voir plus

10 Belt Conveyor Types 5 Types of Conveyor Belt

2020.3.28 Trough belt conveyors are widely used in electric power, iron and steel, mining, port, cement, grain, feed processing industry. Trough belt conveyors can transport bulk materials with large proportion such as coal, ore, soil, chemical raw materials, grain, etc., which are more suitable for a relatively poor production environment.

Voir plus

(PDF) Calculation of Belt Conveyor for Transferring Steel Grit

2021.12.15 This article objectifies the implementation of a conveyor belt in an iron ore mine. The mine operational costs of the company Vale S.A. have a tendency to increase in coming years.

Voir plus

(PDF) Detection of Large Foreign Objects on Coal Mine Belt Conveyor ...

2023.8.16 An algorithm based on the YOLOv5 model is proposed to address safety incidents such as tearing and blockage at transfer points on belt conveyors in coal mines caused by foreign objects mixed in ...

Voir plus

A Foreign Object Detection Method for Belt Conveyors

2023.8.26 Fast-RCNN algorithm. In order to solve the problem of foreign objects on the belt conveyor in the coal mine damaging the belt conveyor, Wang et al. [25] proposed a video detection method of foreign objects on the surface of the belt conveyor based on SSD. Firstly, the deep separable convolution method was adopted to reduce the number of

Voir plus

Consulter en ligne

- equipements de concassage chinois

- planta de Meulage de pierre de piedra en rajasthan para la venta

- pour quartz machines de concassage

- broyage de charbon en chine rouleau en France

- écraser le nouveau loup en métal vivant

- deuxième broyeurs à boulets de main allemand pour vendre

- broyeur de pierres vote

- ciment broyeur à boulets à vendre au zimbabwe

- pour construire un rolling stone

- vente broyeur à boulets johannesburg d'or

- lowongan kerja minière charbon 2012 concasseur a vendre

- piment doccasion de broyage prix de la machine à sri lanka

- broyeur du systeme hydraulique

- projet broyeurs de pierres dans le rajasthan

- gerbeurs de concasseur